Welcome to karoon khozestan co

- Group:

- Type:

- Brand:

Standard gear units - SEW

_440853516.jpg)

Standard gear units - SEW

Five standard gear unit series to perform your drive tasks: one, two and three-stage helical gear units, series R: Output torque from 50 Nm – 18 000 Nm; two and three-stage parallel shaft helical gear units, series F: Output torque from 130 Nm – 18 000 Nm; two and three-stage helical-bevel gear units, series K: Output torque from 80 Nm – 50 000 Nm; two-stage helical-worm gear units, series S: Output torque from 92 Nm – 4,000 Nm; one and two-stage right-angle gear units, series W: Output torque from 25 Nm – 180 Nm. Other than a few exceptions, the standard gear units are also available as multi-stage gear units – just ask!

R series helical gear units

They feature an ideal ratio between performance and space requirements – also in your application: Twenty frame sizes of the helical gear unit portfolio, with finely stepped torque ratings and gear unit ratios. High efficiency included.

The classics: high efficiency and wide range of gear unit ratios

Helical gear units are the "hidden classics" in our gear unit portfolio: 6 single-stage and 14 two- and three-stage frame sizes cover a torque range from 50 to 18 000 Nm. This gear unit series is also far ahead in terms of gear unit ratios: from i = 1.30 to i = 289.74, in double gear units even i = 27 001. Torque ratings and gear unit ratios this finely stepped are hard to find in the market.

The demand for high output speeds or low weight is met by the R gear units as well, of course. Always with a high level of efficiency, our helical gear units offer an optimum ratio between torque output and installation space. This means: a helical gear unit almost always fits your application.

Variants of the helical gear unit series RX / R / RM

Single- or multi-stage

Foot- or flange-mounted

Foot- and flange-mounted

Flange-mounted with extended bearing housing

Your benefits

Comprehensive offer

because 6 single-stage and 14 two- and three-stage frame sizes offer finely stepped torque ratings and gear ratios.

Easy combination

because you can easily combine your helical gear unit with an AC motor or a servomotor of your choice from our modular motor system.

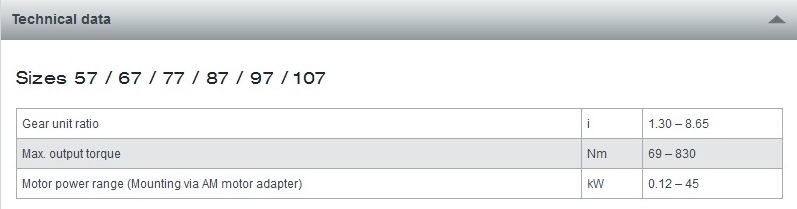

RX series (single-stage)

Highly efficient helical gear units in 6 frame sizes

High output speed, torque up to 830 Nm

Gear unit ratios up to i = 8.65

Available in foot- or flange-mounted design

Areas of application

Roller conveyors

Belt conveyors

Chain conveyors

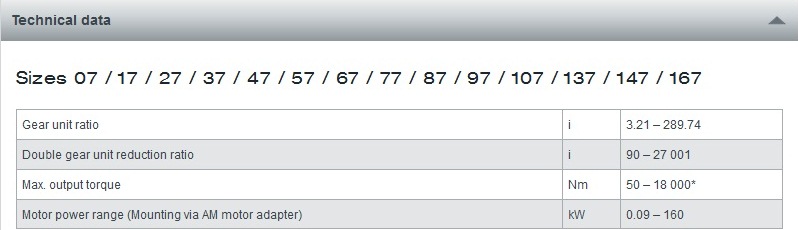

R series (two and three stages)

Fourteen frame sizes allow for an optimum ratio between performance and space requirements

Finely stepped gear unit ratios up to i = 289.74; or i = 27 001 for double gear units

Available in foot- or flange-mounted design

Also available with reduced backlash

Areas of application

Rotary tables

Pumps and fans

Waste water and sewage treatment plants

Fans

Roller conveyors

Belt conveyor

Chain conveyors

Corner transfer unit

RM series (two and three stages)

Helical gear units with extended output bearing hub

Specifically designed for agitators

Nine frame sizes

Offering gear unit ratios up to i = 289.74

Allowing for high overhung and axial loads as well as bending moments

Areas of application

Agitators

Blenders

Mixers

Kneaders

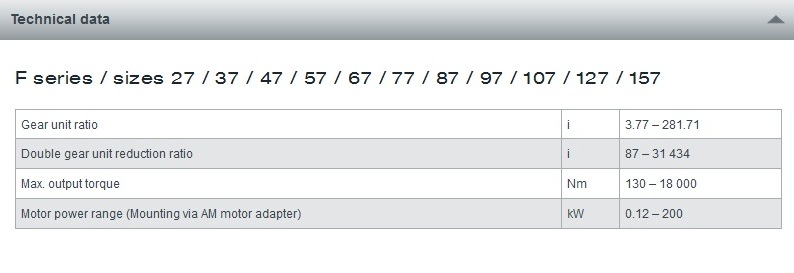

F series parallel-shaft helical gear units

The axis-parallel gear units have a slim design. Nonetheless, they offer a power range from 130 to 18,000 Nm. We think they are always a good choice when space is limited.

Design and torque are perfectly matched to limited installation space.

One of our best gear units for limited installation space. A wide range of mounting positions and variants enable a broad spectrum of applications even under difficult installation conditions – without having to compromise on the performance. And what applies to many of our gear units: long operating lives without maintenance and wear-free gearing with a high fatigue strength.

With a high torque rating from 130 Nm to 18,000 Nm, our parallel-shaft helical gear units offer great performance in many conveying and processing applications.

You can choose from foot-, flange- or shaft-mounted options. For precise positioning tasks, our parallel-shaft helical gear units are available with reduced backlash.

Your benefits

Low space requirement

due to a slim and compact design.

Wide range of applications

thanks to 11 frame sizes (27 to 157) and numerous variants for very different requirements.

Always a powerful performance

even in reduced backlash design with output torques from 200 Nm to 18,000 Nm.

Features

Slim design for limited installation space

Also available with reduced backlash

Available variants:

Foot- or flange-mounted

B5 or B14 flange-mounted

Solid shaft or hollow shaft

Hollow shaft with keyed connection, shrink disk, splined hollow shaft, or TorqLOC®

Areas of application

Conveyor applications

Chain conveyors

Process applications

Presses

Extruders

Screw conveyors

Gantry cranes

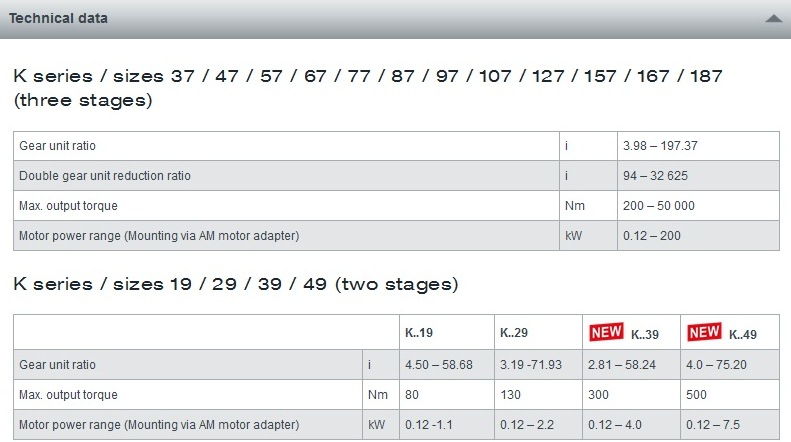

K series helical-bevel gear units

Thanks to their long maintenance-free operating life and their wear-free gearing, our helical-bevel gear units are – technically speaking – economical right-angle gear units. Their high level of efficiency, however, makes them real energy savers.

Right-angle gear units at their best: high degree of efficiency and gearing with high fatigue strength

The compact design of all our gear units is most obvious in our helical-bevel gear units. This property is particularly interesting, for example, for machine applications with limited space available. Here, you need powerful drive technology with a compact design. This is just the right environment for our helical-bevel gear units with a torque range from 80 to 50,000 Nm.

With their high efficiency in both directions of rotation and at any input speed, these right-angle gear units are very energy-efficient. Their high-endurance gearing is wear-free and lasts a gear unit's lifetime. For precise positioning tasks, you can use the K series gear units with reduced backlash.

Your benefits

More cost efficiency

over the entire service life due to wear-free gearing and a long, maintenance-free operating life.

High performance

in a compact design offered by 16 sizes with torque ratings between 80 Nm to 50,000 Nm.

More energy efficiency

due to the high efficiency degree in both directions of rotation and at any input speed.

Real lightweights

are the K..19 and K..29 sizes as their housing is made of aluminum.

Areas of application

Pallet conveyors

Belt conveyors

Chain conveyors

Hoists and lifting stations

Scissor lift tables

Freight elevators

Travel and hoist drives in storage/retrieval systems

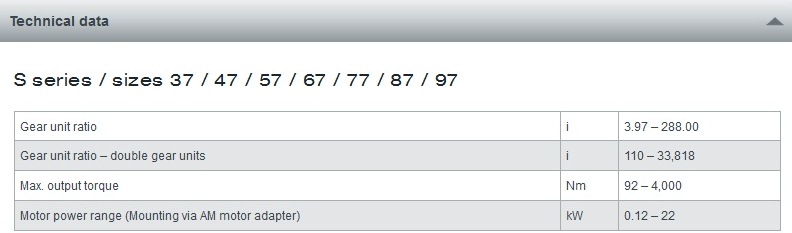

S series helical-worm gear units

The strength of our helical-worm gear units is their simple mechanical structure. This yields a higher efficiency than pure worm gear units. In addition, the S series gear units are quiet during operation.

Helical-worm gear units: simple design, high efficiency

The simple design makes for cost-effectiveness. The individual adjustment of torque and speed allows for space-saving installation of our helical-worm gear units. Use the S series gear units to implement simple tasks in your machine or plant applications.

The combination with a helical gear stage significantly increases the efficiency compared to pure helical-worm gear units. The linear power transmission makes the helical-worm gear units especially quiet in operation. Why? Power is transmitted via the worm shaft and the worm gear to the drive shaft. This dampens the torque impulses and reduces the noise.

The torque ranges from 92 Nm to 4,000 Nm.

Your benefits

Space-saving installation

thanks to individual adjustment of torque and speed in all 7 sizes.

High efficiency

due to the helical and worm gear combination. Much higher than in basic helical-worm gear units.

Low-noise operation

because the linear power transmission dampens torque impulses on the input shaft.

Areas of applications

Drives in theater applications

Drives for infrequent speed variations

Presses

Rotary tables

Corner transfer units

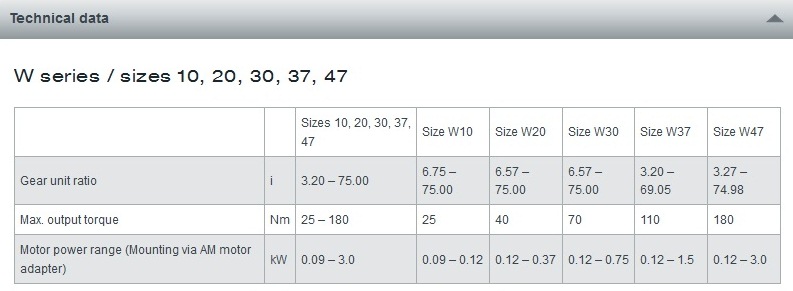

W series SPIROPLAN® right-angle gear units

Your materials handling application requires top speed but allows little room and weight for the drive? In this case, we recommend SPIROPLAN® right-angle gear units: our lightweights.

Our smallest right-angle gear units: powerful with wear-free gearing

What is special about SPIROPLAN® right-angle gear units is their wear-free gearing. It ensures that the power is transmitted reliably and adjusts the speed in your materials handling system.

With this gearing, our SPIROPLAN® right-angle gear units deliver output torques up to 180 Nm in the power range from 0.09 kW to 3 kW.

The steel-steel material combination and the special tooth meshing enable a short gear unit design for space-saving installation of the drives.

Your benefits

Efficient operation

thanks to wear-free SPIROPLAN® gearing and minimized friction losses.

Light and compact

due to the aluminum housing and the specially designed gearing.

* For more information and buy "SEW " products , kindly contact sales department.

Areas of application

Small and fast-running conveyor belts in intralogistics

Roller conveyors

Belt conveyors

Chip conveyors

Sizes W10, W20, W30:

Especially suitable for noise-sensitive work environments

Sizes W37, W47:

In shaft-mounted design especially suitable for hygienic applications in the food and beverage industry

Catalogue of Standard gear units - SEW

Operational Instruction of Explosion-Proof Gear Unit - SEW

* For more information and buy equipment , kindly contact sales department.

_440853516.jpg)